1. Ububanzi

Ukucaciswa kufaka phakathi i-NPS 10~NPS48 Ejwayelekile Yobubanzi, I-Normal Pressure Class (150LB~300LB) enamavalvu evemvane ensimbi eccentric ephindwe kathathu.

2. Incazelo Yomkhiqizo

2.1 Izidingo zobuchwepheshe

2.1.1 Idizayini kanye nezinga Lokukhiqiza:API 609

2.1.2 Izinga lokuxhuma ekupheleni ukuya ekupheleni:ASME B16.5

2.1.3 Izinga lobukhulu bobuso nobuso:API609

2.1.4 Izinga lezinga le-pressure-temperature:ASME B16.34

2.1.5 Ukuhlolwa nokuhlolwa (kuhlanganise nokuhlolwa kwe-hydraulic): API 598

2.2 Umkhiqizo Ojwayelekile

Ivalve yevemvane eyi-triple eccentric ene-double metal sealing ingenye yemikhiqizo emikhulu ye-BVMC, futhi isetshenziswa kabanzi kwezensimbi, imboni yokukhanya, amandla kagesi, i-petrochemical, isiteshi segesi neminye imikhakha.

3. Izimpawu kanye nesicelo

Isakhiwo sine-eccentric kathathu futhi sihlezi ngensimbi.Inokusebenza okuhle kokuvala ngaphansi kwesimo sokushisa kwegumbi kanye/noma izinga lokushisa eliphezulu.Ivolumu encane, isisindo esincane, ukuvula nokuvala ngokuguquguqukayo nokuphila okude kokusebenza kuyizinzuzo zayo ezisobala uma kuqhathaniswa namavalvu esango noma ama-valve eglobhu.Isetshenziswa kabanzi kwezensimbi, imboni yokukhanya, amandla kagesi, i-petrochemical, isiteshi segesi yamalahle neminye imikhakha, ukusetshenziswa kokuphepha okuthembekile, i-valve iyisinqumo esifanele samabhizinisi anamuhla.

4.Isakhiwo

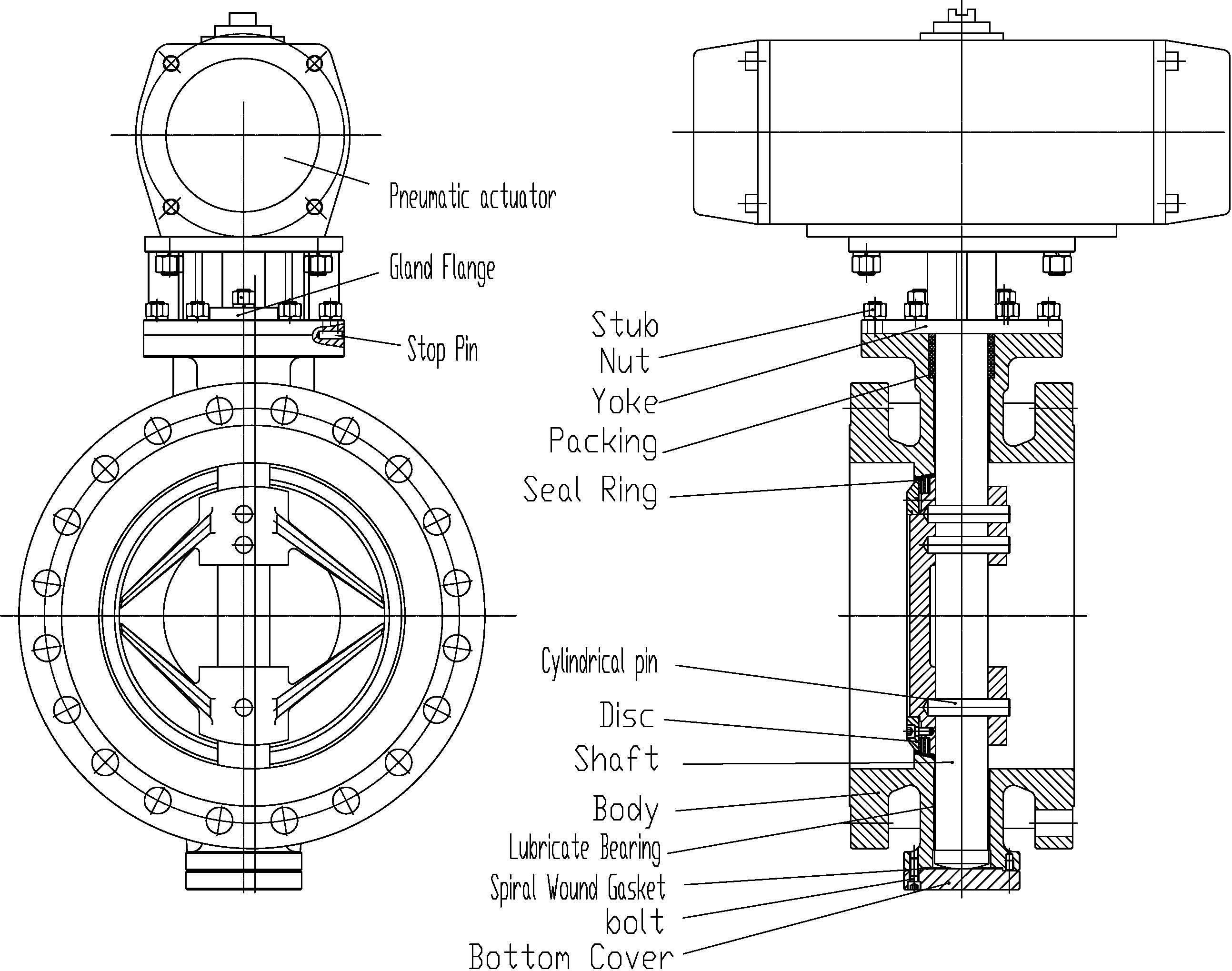

4.1 I-valve ye-butterfly evala uphawu yensimbi kathathu njengoba kukhonjisiwe ku-Sketch 1

Umfanekiso 1 Ivalvu yevemvane eyinsimbi ene-eccentric kathathu

5. Umgomo wokuvala:

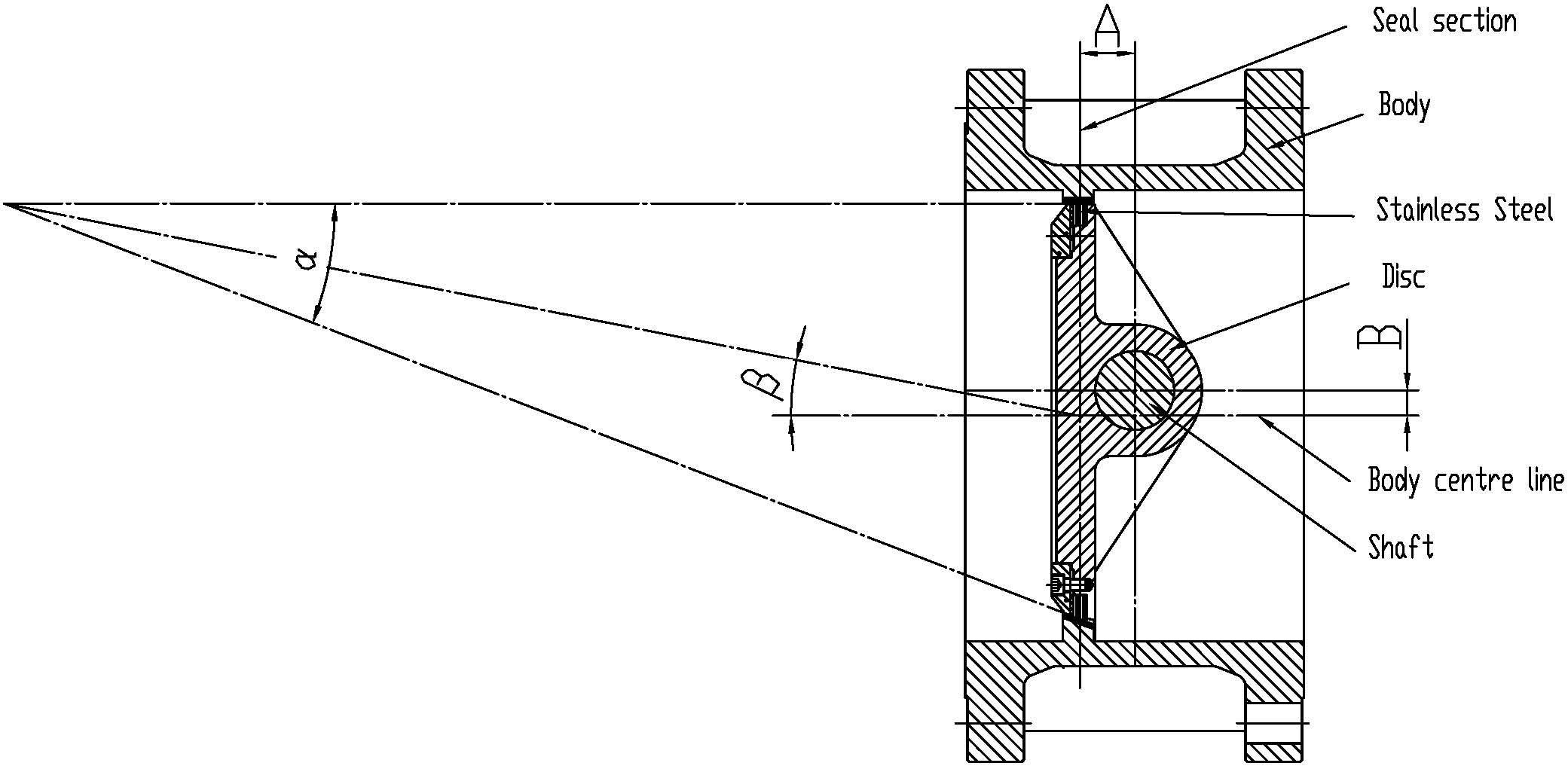

Umfanekiso 2 Ivalve uvemvane yensimbi ene-eccentric ephindwe kathathu iwumkhiqizo ojwayelekile we-BVMC, njengoba kukhonjisiwe ku-sketch 2.

(a) Izici Zesakhiwo: Isikhungo sokuzungezisa sepuleti uvemvane (okungukuthi isikhungo se-valve) siwukwenza ukuchema A endaweni yokuvala ipuleti levemvane, kanye nokuchema B ngomugqa omaphakathi womzimba wevalvu.Futhi i-engeli engu-βbe idalwe phakathi komugqa omaphakathi wobuso bophawu nomzimba wesihlalo (okungukuthi, umugqa we-axial womzimba)

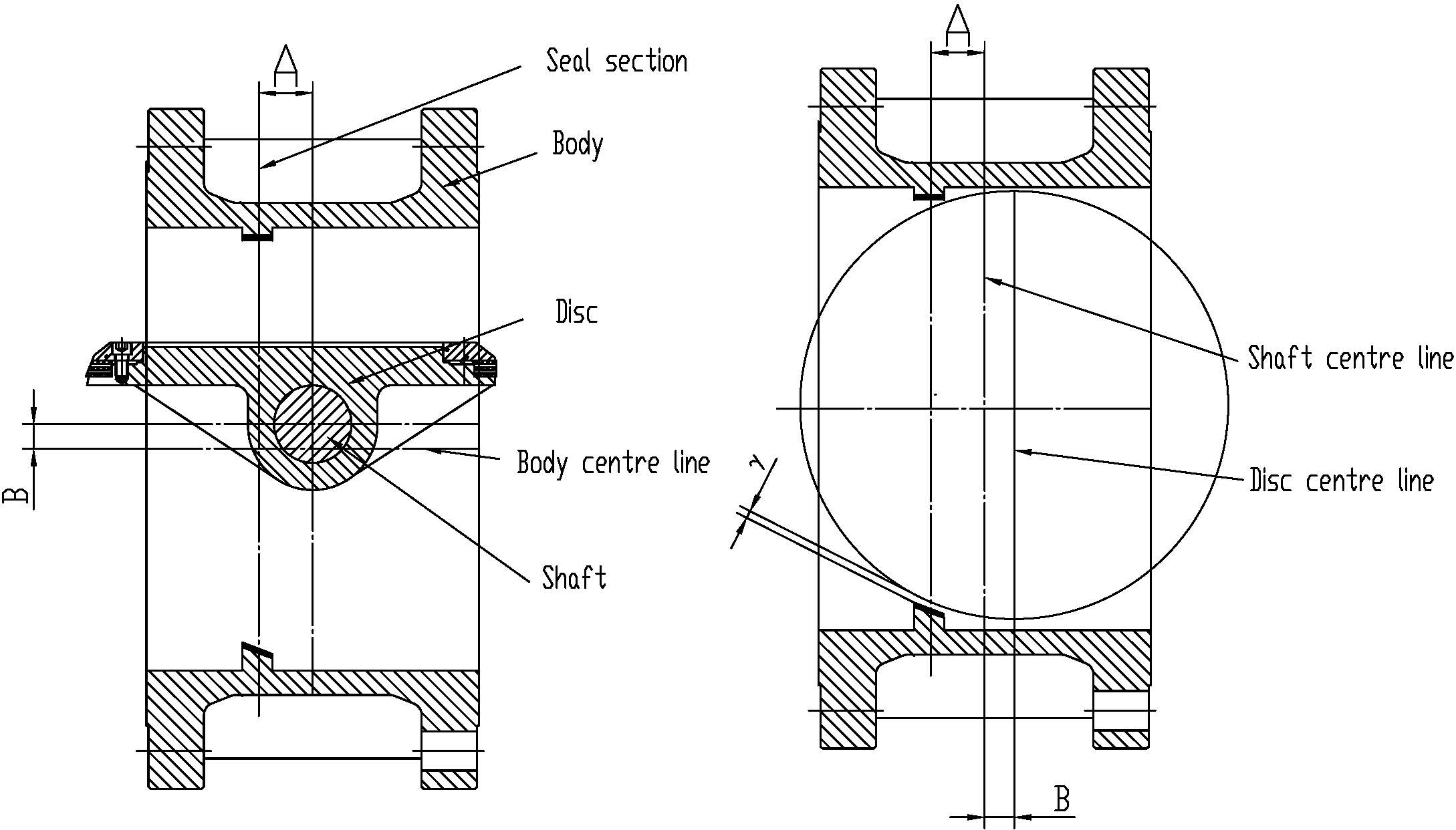

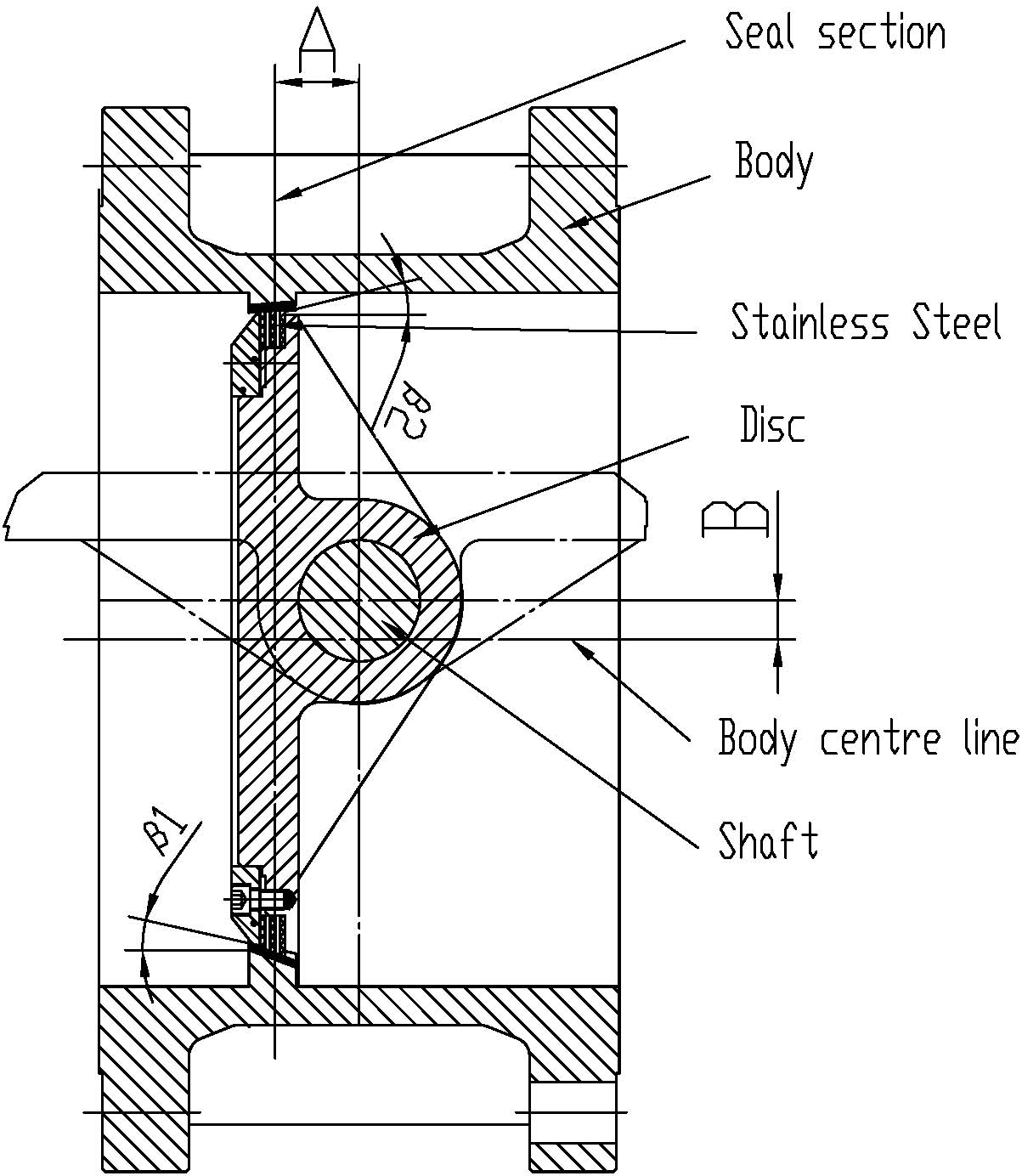

(b) Isimiso sokuvala: Ngokusekelwe ku-valve uvemvane oyi-eccentric kabili, i-valve uvemvane eccentric kathathu yenze i-Angleβ phakathi kwemigqa emaphakathi yesihlalo nomzimba.Umphumela wokuchema unjengoba kukhonjisiwe kumfanekiso wesi-3 esiphambanweni.Uma i-valve uvemvane eccentric eccentric kathathu isendaweni evuleke ngokugcwele, indawo yokuvalwa kwepuleti levemvane izohlukaniswa ngokuphelele nendawo yokuvala isihlalo se-valve.Futhi kuzokwenziwa imvume γ phakathi kobuso obuvalekayo bepuleti levemvane nendawo evalekayo yomzimba okufana ne-valve uvemvane eccentric kabili.Njengoba kuboniswe emfanekisweni 4, ngenxa yokwakheka kwe-engeli engu-β, ama-engeliβ1 kanye no-β2 azokwakheka phakathi komugqa we-tangent wethrekhi yokuzungezisa idiski kanye nendawo yokuvala isihlalo sevalvu.Lapho uvula futhi uvala idiski, indawo yokuvalwa kwepuleti levemvane izohlukana kancane kancane futhi iminyene, bese iqeda ngokuphelele ukuguga nokuhuzuka.Lapho i-valve ivuleka, indawo yokuvala i-disc izohlukana ngokushesha nesihlalo se-valve.Futhi kuphela ngesikhathi esivalwe ngokugcwele, i-disc izohlangana esihlalweni.Njengoba kuboniswe kumfanekiso4, ngenxa yokwakheka kwe-engeli β1 kanye no-β2, lapho i-valve yovemvane ivaliwe, ukucindezela kophawu kukhiqizwa ukukhiqizwa kwe-torque ye-valve shaft hhayi ukuguquguquka kwesihlalo se-butterfly valve.Akukwazi nje kuphela ukuqeda amathuba okunciphisa umphumela we-seal kanye nokwehluleka okubangelwa ukuguga kwezinto zokuhlala, ukugeleza okubandayo, izici ezingavumelekile zokunwebeka, futhi ingalungiswa ngokukhululekile nge-torque ye-drive, ukuze ukusebenza kokuvalwa kwe-butterfly valve eccentric kanye nempilo yokusebenza kuyoba kakhulu. ngcono.

Umfanekiso 2 Ivalve uvemvane enendlela ephindwe kabili yensimbi evalwe kabili

Umdwebo 3 Umdwebo wevalve uvemvane evalekile enensimbi ephindwe kathathu endaweni evulekile

Umfanekiso 4 Umdwebo we-valve uvemvane oyinsimbi ephindwe kabili eccentric ngesikhathi esiseduze

6.1 Ukufakwa

6.1.1 Ukubheka ngokucophelela okuqukethwe kwe-nameplate yevalvu ngaphambi kokufaka, qinisekisa ukuthi uhlobo, ubukhulu, isihlalo kanye nezinga lokushisa kwevalvu kuzohambisana nesevisi yepayipi.

6.1.2 Ukuhlola okungcono kakhulu ukuthi wonke amabhawodi axhumekile ngaphambi kokufakwa, uqinisekise ukuthi aqina ngokulinganayo.Nokuhlola ukuthi ukucindezelwa nokuvala ukupakisha.

6.1.3 Ivalvu ehlolayo enamamaki okugeleza, njengeekhombisa lapho igeleza khona,

Futhi ukufaka i-valve kufanele kuhambisane nezinhlinzeko zokugeleza.

6.1.4 Ipayipi kufanele lihlanzwe futhi likhishwe uwoyela walo, i-slag yokushisela nokunye ukungcola ngaphambi kokufakwa.

6.1.5 Ivalvu kufanele ikhishwe ngobumnene, ivimbele ukuyiphonsa nokuwisa.

6.1.6 Kufanele sikhiphe isembozo sothuli ekugcineni kwevalvu lapho sifaka ivalvu.

6.1.7 Uma ufaka i-valve, ubukhulu be-gasket ye-flange bungaphezu kuka-2 mm futhi ukuqina kosebe kungaphezu kuka-70 PTFE noma i-gasket ephendukayo, i-flange yamabholithi axhumayo kufanele aqiniswe ngokulinganayo.

6.1.8 Ukuxega kokupakisha kungase kubangelwe ukushintsha kokudlidliza nezinga lokushisa ekuthuthweni, nokuqinisa amantongomane endlala yokupakisha uma kukhona ukuvuza ekuvaleni kwesiqu ngemva kokufakwa.

6.1.9 Ngaphambi kokufaka ivalvu, indawo ye-actuator yomoya kufanele isethwe, ukuze kusebenze okuzenzela kanye nokugcinwa kusesimweni esingalindelekile.Futhi i-actuator kufanele ihlolwe futhi ihlolwe ngaphambi kokufakwa ekukhiqizeni.

6.1.10 Ukuhlola okungenayo kufanele kuhambisane nezindinganiso ezifanele.Uma indlela ingalungile noma ibangelwe ngumuntu, i-BVMC Company ngeke ithathe noma yimuphi umthwalo.

6.2 Ukugcina kanye Nokunakekela

6.2.1 Iziphetho kufanele zimbozwe ngekhava yothuli ekamelweni elomile nelinomoya, ukuqinisekisa ukuhlanzeka kwesikhala sevalvu.

6.2.2 Uma i-valve yokugcina isikhathi eside iphinda isetshenziswa, ukupakisha kufanele kubhekwe ukuthi akuvumelekile yini bese kugcwala uwoyela wokuthambisa ezingxenyeni ezijikelezayo.

6.2.3 Amavalvu kufanele asetshenziswe futhi agcinwe ngesikhathi sewaranti (ngokwenkontileka), okuhlanganisa ukushintshwa kwe-gasket, ukupakisha njll.

6.2.4 Izimo zokusebenza zevalvu kufanele zihlale zihlanzekile, ngoba zingelula isikhathi sokusebenza kwayo.

6.2.5 Amavalvu kudingeka ahlole futhi agcinwe njalo lapho esebenza ukuze avikeleke ekugqwaleni futhi aqinisekise ukuthi okokusebenza kusesimweni esihle.

Uma okuphakathi kungamanzi noma uwoyela, kuphakanyiswa ukuthi ama-valve kufanele ahlolwe futhi agcinwe njalo ezinyangeni ezintathu.Futhi uma i-medium igqwala, kuphakanyiswa ukuthi wonke ama-valve noma ingxenye yama-valve kufanele ihlolwe futhi igcinwe njalo ngenyanga.

6.2.6 Ivalvu yokucindezela isihlungi somoya kufanele idonse njalo, ikhiphe ukungcola, ithathele indawo into yokuhlunga.Ukugcina umoya uhlanzekile futhi womile ukuze ugweme ukungcola izingxenye ze-pneumatic, imbangela yokwehluleka.(Ukubona "umyalelo wokusebenza kwe-pneumatic actuator")

6.2.7 Isilinda, izingxenye ze-pneumatic kanye namapayipi kufanele kuhlolwe ngokucophelela futhi njalo ukuze kuvinjelwe ukuvuza kwegesi (Ukubona "umyalelo wokusebenza kwe-pneumatic actuator")

6.2.8 Lapho kulungiswa amavalvu kufanele aphinde ashaye izingxenye zomzimba, asuse umzimba wangaphandle, amabala kanye nendawo egqwalile.Ukushintsha ama-gaskets awonakele kanye nokupakisha, indawo yokuvala uphawu kufanele ilungiswe.Ukuhlolwa kwe-hydraulic kufanele kwenziwe futhi ngemuva kokulungiswa, abaqeqeshiwe bangasebenzisa.

6.2.9 Umsebenzi wengxenye yevalvu (njengesiqu kanye ne-packing seal) kufanele ihlale ihlanzekile futhi isule uthuli ukuze ivikeleke ekulimazeni nasekugqwaleni.

6.2.10 Uma kukhona ukuvuza ekupakisheni futhi amantongomane endlala yokupakisha kufanele aqiniswe ngqo noma ashintshe ukupakisha kuye ngokwesimo.Kodwa Akuvunyelwe ukushintsha ukupakisha ngengcindezi.

6.2.11 Uma ukuvuza kwevalvu kungaxazululwanga ku-inthanethi noma kwezinye izinkinga zokusebenza, lapho kukhishwa ivalvu kufanele kuhambisane nezinyathelo ezilandelayo:

a.Naka ukuphepha: ukuze uphephe, ukukhipha ivalvu epayipini kuqala kufanele kuqonde ukuthi yini indawo ephakathi kwepayipi.Kufanele ugqoke izinto zokuvikela abasebenzi ukuze uvimbele okuphakathi komonakalo wepayipi.Ngesikhathi esifanayo ukuqinisekisa ukuthi ipayipi medium ingcindezi kakade.I-valve kufanele ivalwe ngokugcwele ngaphambi kokukhipha i-valve.

b.Ukukhipha idivayisi yomoya (kuhlanganise nomkhono wokuxhuma, Ukubona "umyalelo wokusebenza kwe-pneumatic actuator") kufanele uqaphele ukuthi usebenza ukuze ugweme ukulimala okuvela esiqwini kanye nesisetshenziswa somoya;

c.Indandatho yokuvala yediski kanye nesihlalo kufanele kubhekwe uma kukhona ukuklwebheka lapho ivalve uvemvane ivuliwe.Uma kunokuklwebheka okuncane kwesihlalo, kungasebenzisa indwangu ye-emery noma uwoyela endaweni yokuvala ukuze kulungiswe.Uma kuvela ukuklwebheka okujulile okumbalwa, izinyathelo ezifanele kufanele zithathwe ukuze kulungiswe, i-valve uvemvane ingasebenzisa ngemva kokuhlolwa okufanelekile.

d.Uma isiqu esipakishwayo sivuza, indlala yokupakisha kufanele isuse, bese ubheka isiqu nokupakishwa kwendawo, uma isiqu sinokuklwebheka, i-valve kufanele ihlangane ngemva kokulungiswa.uma ukupakisha konakele, ukupakisha kufanele kushintshwe.

e.Uma isilinda sinezinkinga, kufanele sihlole izingxenye zomoya, siqinisekise ukuthi ukugeleza kwendlela yegesi nomfutho womoya, i-electromagnetic reverse valve valve ijwayelekile.Ukubona "umyalelo wokusebenza kwe-pneumatic actuator")

f.Lapho igesi ifakwa emshinini womoya, yenza isiqiniseko sokuthi isilinda akukho ngaphakathi nangaphandle akuvuzi.Uma idivayisi yomoya seal ilimele kungaholela ekwehleni ukusebenza torque ingcindezi, ukuze ingahlangani uvemvane valve ukuvulwa kanye nokuvala ukusebenza, kufanele sinake ukuhlolwa njalo kanye izingxenye esikhundleni.

I-valve uvemvane womoya ezinye izingxenye ngokuvamile azilungisi.Uma umonakalo umkhulu, kufanele uxhumane nefekthri noma uthumele ekulungisweni kwefekthri.

6.2.12 Isivivinyo

I-valve izoba ukuhlolwa kokucindezela ngemva kokuba i-valve ilungise ukuhlolwa ngokuhambisana nezindinganiso ezifanele.

6.3 Imiyalelo yokusebenza

6.3.1 Ivalvu esebenza emoyeni enomshayeli wedivaysi yesilinda izokwenziwa ukuthi idiski izungeziswe ngo-90° ukuze ivule noma ivale ivalvu.

6.3.2 Izikhombisi-ndlela ezivulekile zevalvu uvemvane olusebenza nomoya kufanele zimakwe ngenkomba yendawo kudivayisi yomoya.

6.3.3 I-valve uvemvane ene-truncation kanye nesenzo sokulungisa ingasetshenziswa njengendlela yokushintsha uketshezi kanye nokulawula ukugeleza.Ngokuvamile akuvunyelwe ukudlula ingcindezi - isimo somngcele wezinga lokushisa noma ingcindezi eshintshashintshayo kanye nezimo zokushisa

6.3.4 I-valve ye-Butterfly inamandla okumelana nomehluko we-high pressure, ungavumeli i-valve uvemvane ivuleke ngaphansi komehluko we-high-pressure ngisho noma umehluko wengcindezi ephezulu uyaqhubeka nokujikeleza.Uma kungenjalo kungabangela umonakalo, noma ngisho nengozi embi kakhulu yokuphepha kanye nokulahlekelwa kwempahla.

6.3.5 Amavalvu womoya asetshenziswa njalo, futhi ukusebenza kokunyakaza nezimo zokugcoba kufanele zihlolwe njalo.

6.3.6 Idivayisi yomoya ngokwewashi ukuze ivalve uvemvane ivaleke, ngokuphambene newashi ukuze ivalve uvemvane ivuleke.

6.3.7 Ukusebenzisa i-valve uvemvane womoya kufanele unake umoya uhlanzekile, umfutho wokunikezwa komoya ungu-0.4 ~ 0.7 Mpa.Ukugcina amaphaseji omoya evulekile, akuvunyelwe ukuvimba ukungena komoya nokugeleza komoya.Ngaphambi kokusebenza, idinga ukungena emoyeni ocindezelwe ukubona ukuthi ukunyakaza kwe-butterfly valve ye-pneumatic kuyinto evamile.qaphela i-valve uvemvane womoya evulekile noma evaliwe, kungakhathaliseki ukuthi idiski ivuliwe ngokugcwele noma ivaliwe.Ukunaka isikhundla se-valve kanye nesimo se-cylinder sihambisana.

6.3.8 Isakhiwo se-pneumatic actuators crank arm iyikhanda elingunxande, elisetshenziselwa umshini osebenza ngesandla.Uma kwenzeka ingozi, ingasusa ipayipi lokuhambisa umoya ngokuqondile ngesikrufu ukuthi ukusebenza kwezandla kungenziwa.

7. Amaphutha, izizathu kanye nesixazululo (Bheka ithebhu 1)

Ithebhu 1 Izinkinga ezingenzeka, izimbangela nezixazululo

| Amaphutha | Imbangela yokwehluleka | Isixazululo |

| I-valve ehamba ngama-valve inzima, ayiguquguquki | 1. Ukwehluleka kwe-Actuator2.Vula i-torque inkulu kakhulu3.Umfutho womoya uphansi kakhulu 4.Ukuvuza kwesilinda | 1. Lungisa futhi uhlole isifunda sikagesi kanye nesekhethi yegesi ye-pneumatic device2.Ukunciphisa ukulayishwa komsebenzi nokukhetha imishini yomoya ngendlela efanele3.Khulisa umfutho womoya 4. Hlola izimo zokuvala isilinda noma umthombo wejoyinti |

| I-Stem Packing Leakage | 1. Ukupakisha amabhawodi edlala kukhululekile2.Ukupakisha umonakalo noma isiqu | 1. Qinisa amabhawodi edlala2.Faka esikhundleni sokupakisha noma isiqu |

| Ukuvuza | 1.Indawo yokuvala yesekela lokuvala ayilungile | 1. Ukulungisa i-actuator ukwenza indawo yokuvala yesekela lokuvala kulungile |

| 2. Ukuvala akufiki endaweni ebekiwe | 1.Ukuhlola isiqondiso se-open-close kusendaweni2.Ukulungisa ngokuvumelana nemininingwane ye-actuator, ukuze isiqondiso sivunyelaniswe nesimo se-open3 yangempela.Ukuhlola izinto ezibambayo kusendleleni | |

| 3. Izingxenye zokulimala kwe-valve①Ukulimala kwesihlalo②Ukulimala kwediski | 1. Shintsha isihlalo2.Faka esikhundleni idiski | |

| I-Actuator iphelile | 1.Ukulimala kokhiye kanye ne-drop2.Iphinikhodi yokumisa inqanyuliwe | 1. Faka esikhundleni ukhiye phakathi kwesiqu kanye ne-actuator2.Faka esikhundleni iphinikhodi yokumisa |

| Ukwehluleka kwedivayisi yomoya | Ukubona "izicaciso zedivayisi ye-valve pneumatic" | |

Qaphela: Abasebenzi besondlo bazoba nolwazi olufanele kanye nesipiliyoni.

Isikhathi sokuthumela: May-19-2022