1. Ububanzi

Le manuwali ihlanganisa amavalvu amabhola e-trunnion asebenza ngogesi, asebenza emoyeni, asebenza nge-hydraulic kanye negesi kawoyela esebenza nge-flanged ama-valve ebhola enziwe nge-trunnion eyizingcezu ezintathu kanye nama-valve amabhola ashiselwe ngokugcwele anosayizi wegama elithi NPS 8~36 & Class 300~2500.

2. Incazelo Yomkhiqizo

2.1 Izidingo zobuchwepheshe

2.1.1 Idizayini kanye nezinga Lokukhiqiza : API 6D, ASME B16.34

2.1.2 Izinga lokuxhuma ekupheleni ukuya ekupheleni: ASME B16.5

2.1.3 Izinga lobukhulu bobuso nobuso: ASME B16.10

2.1.4 Izinga lezinga le-pressure-temperature: ASME B16.34

2.1.5 Ukuhlola nokuhlola (kuhlanganise nokuhlolwa kwe-hydraulic): API 6D

2.1.6 Ukuhlolwa kokumelana nomlilo: API 607

2.1.7 Ukucubungula ukumelana nesibabule kanye nokuhlolwa kwezinto (okusebenzayo kusevisi emuncu): NACE MR0175/ISO 15156

2.1.8 Ukuhlolwa kokuphuma kwemfucumfucu (okusebenzayo kusevisi emuncu): njengokusho kwe-BS EN ISO 15848-2 Ikilasi B.

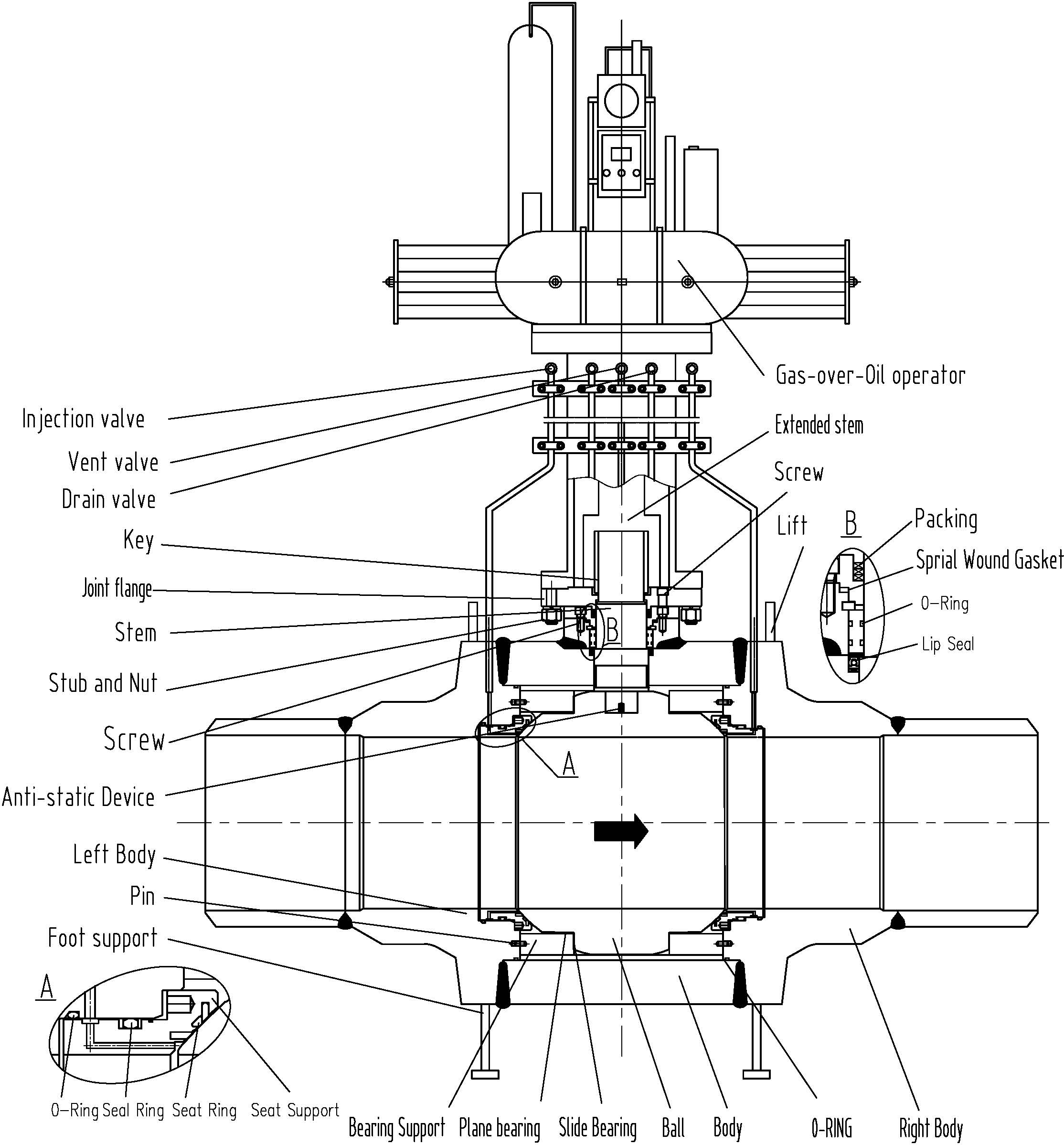

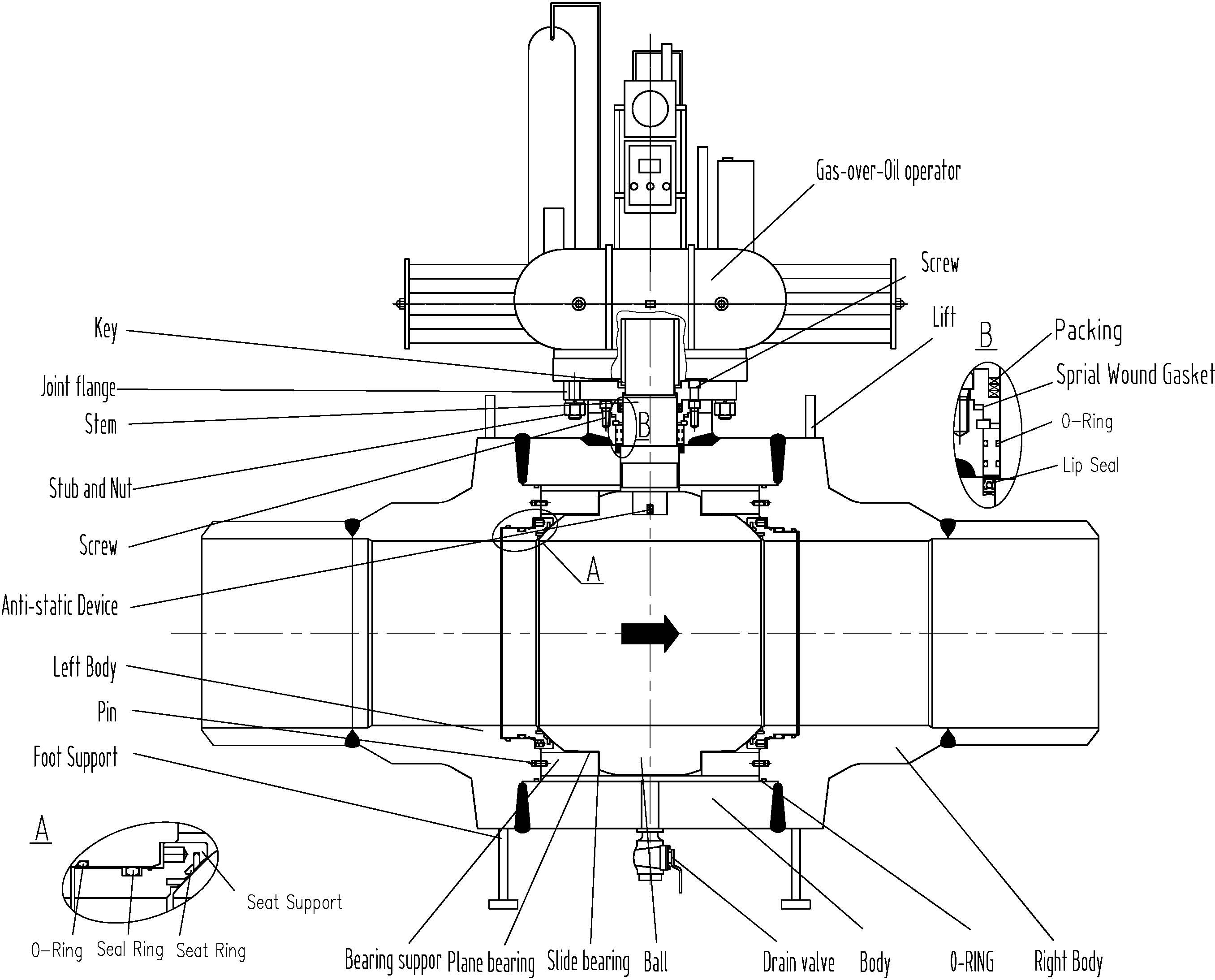

2.2 Ukwakheka kwe-valve yebhola

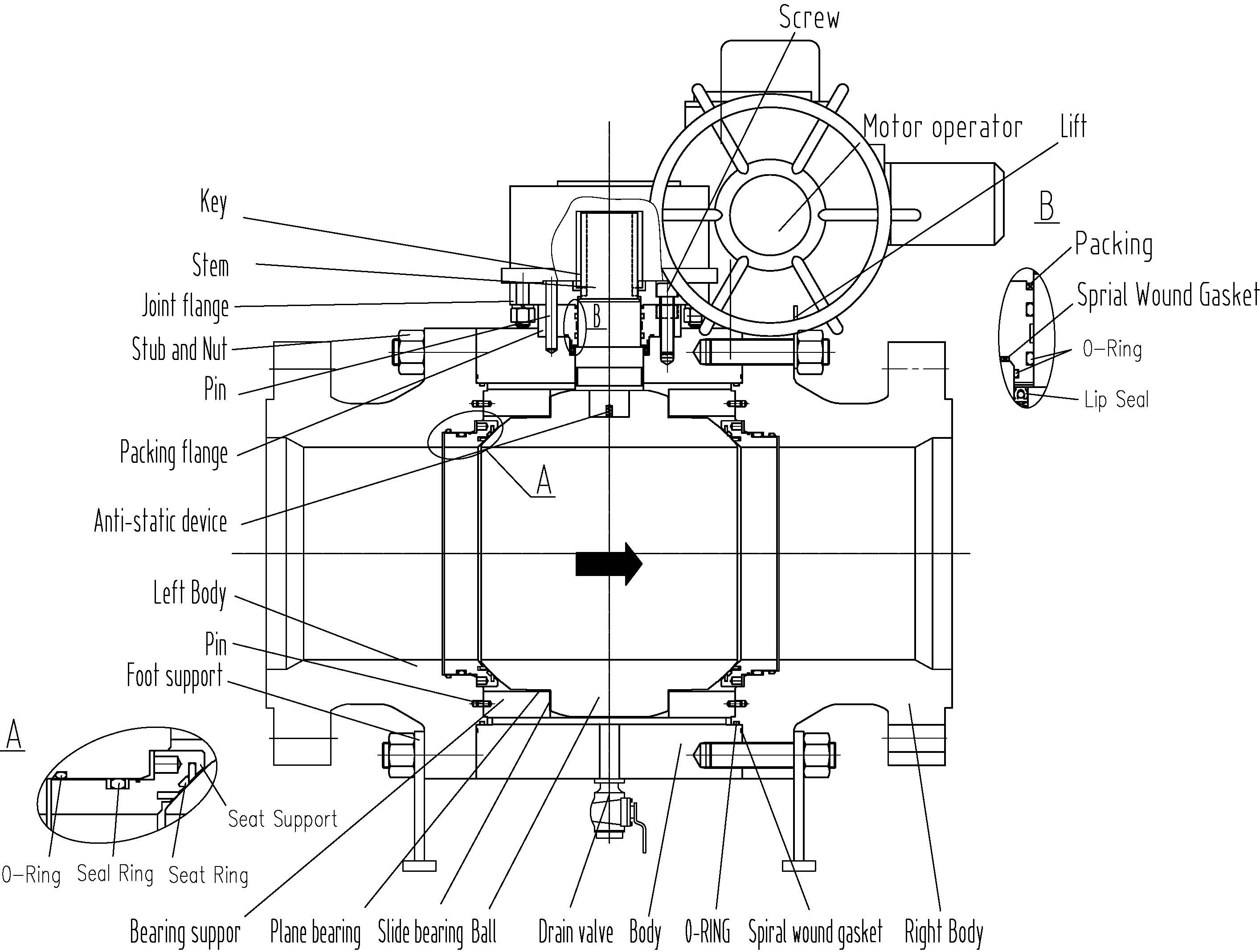

Umfanekiso1 Izingcezu ezintathu zamavalvu ebhola enziwe nge-trunnion acushwe ngogesi

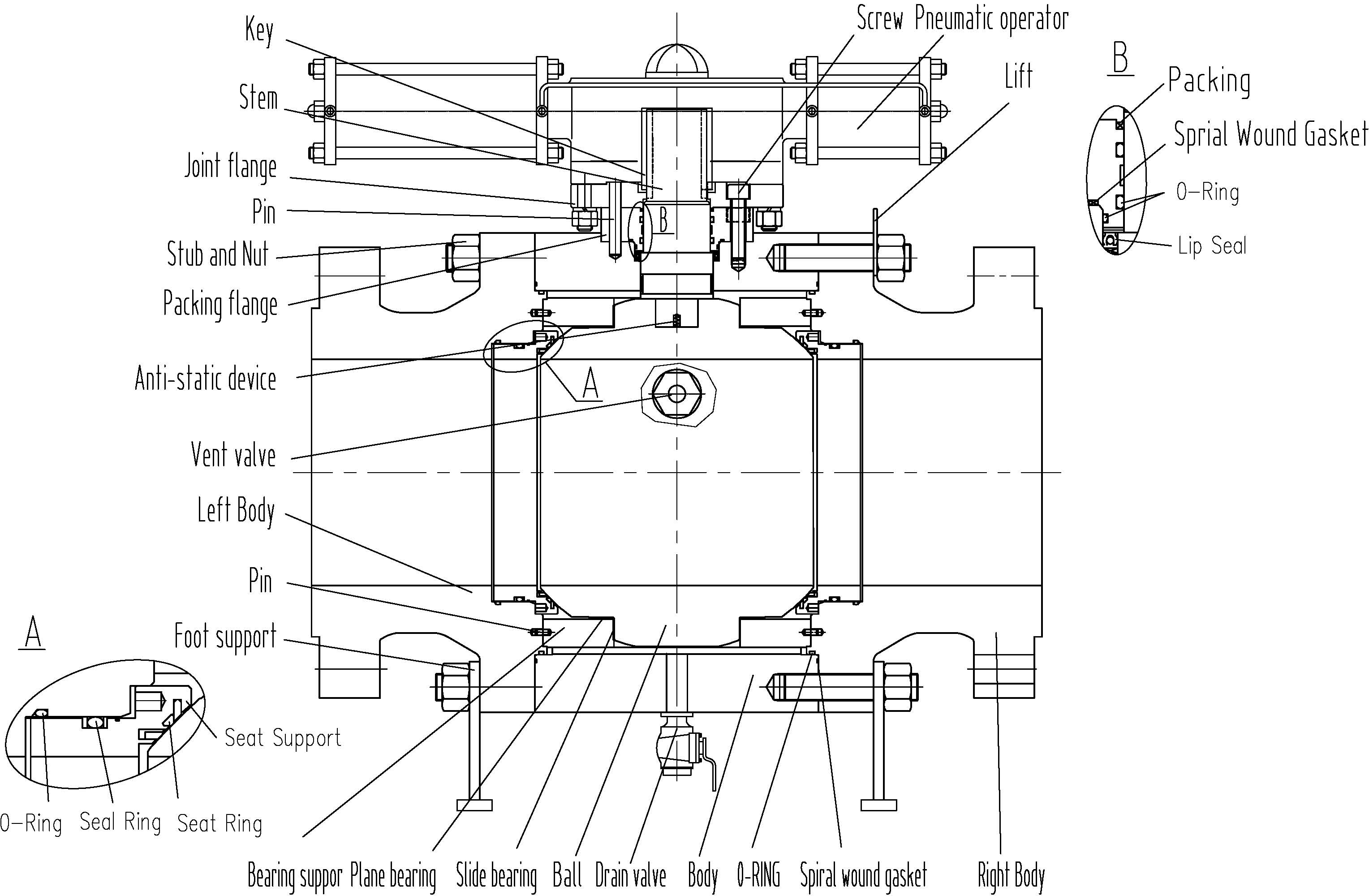

Umfanekiso 2 Izingcezu ezintathu zamavalvu ebhola enziwe nge-trunnion avuswe umoya

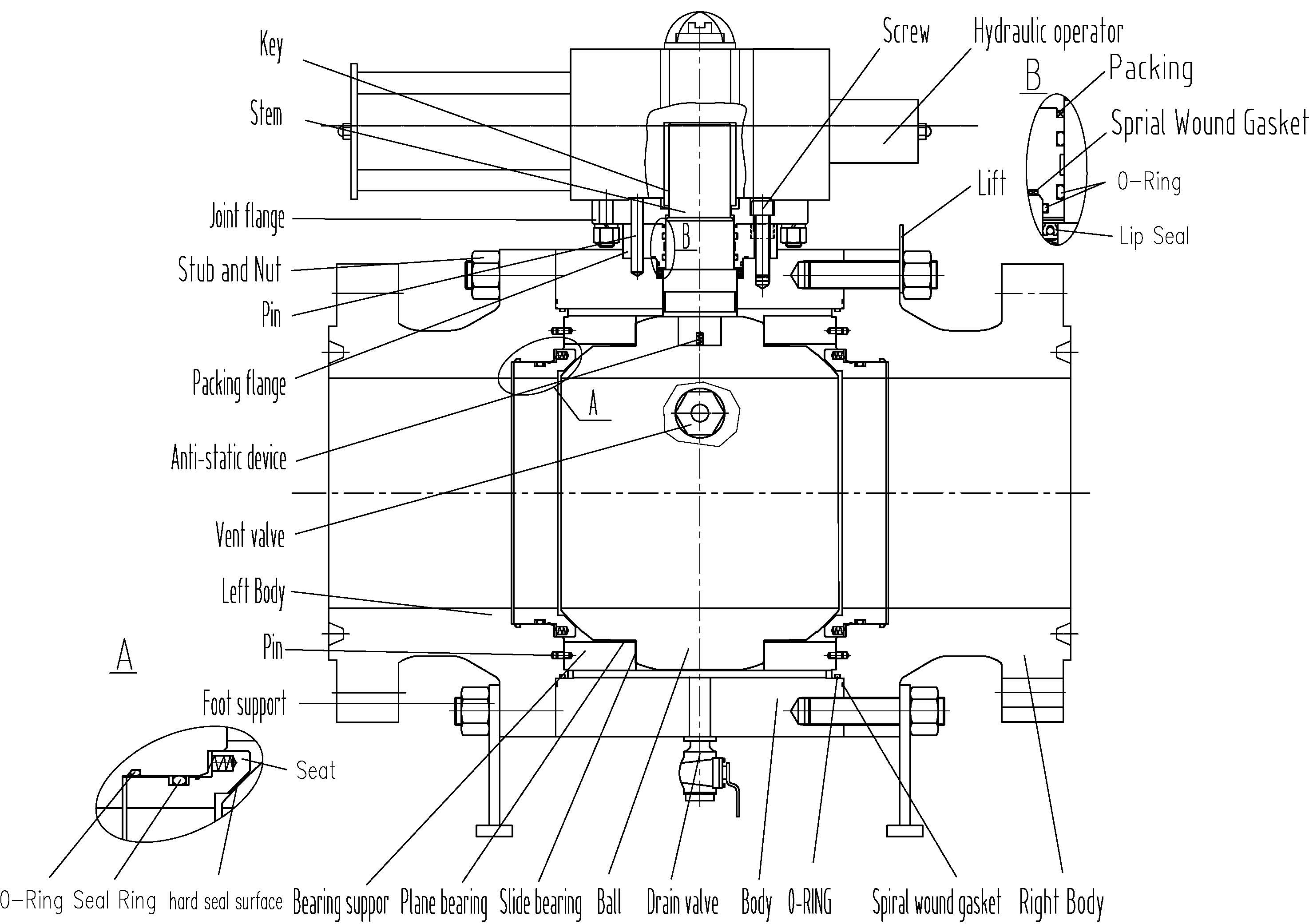

Umfanekiso 3 Izingcezu ezintathu zamavalvu ebhola enziwe nge-trunnion ane-hydraulic actuated

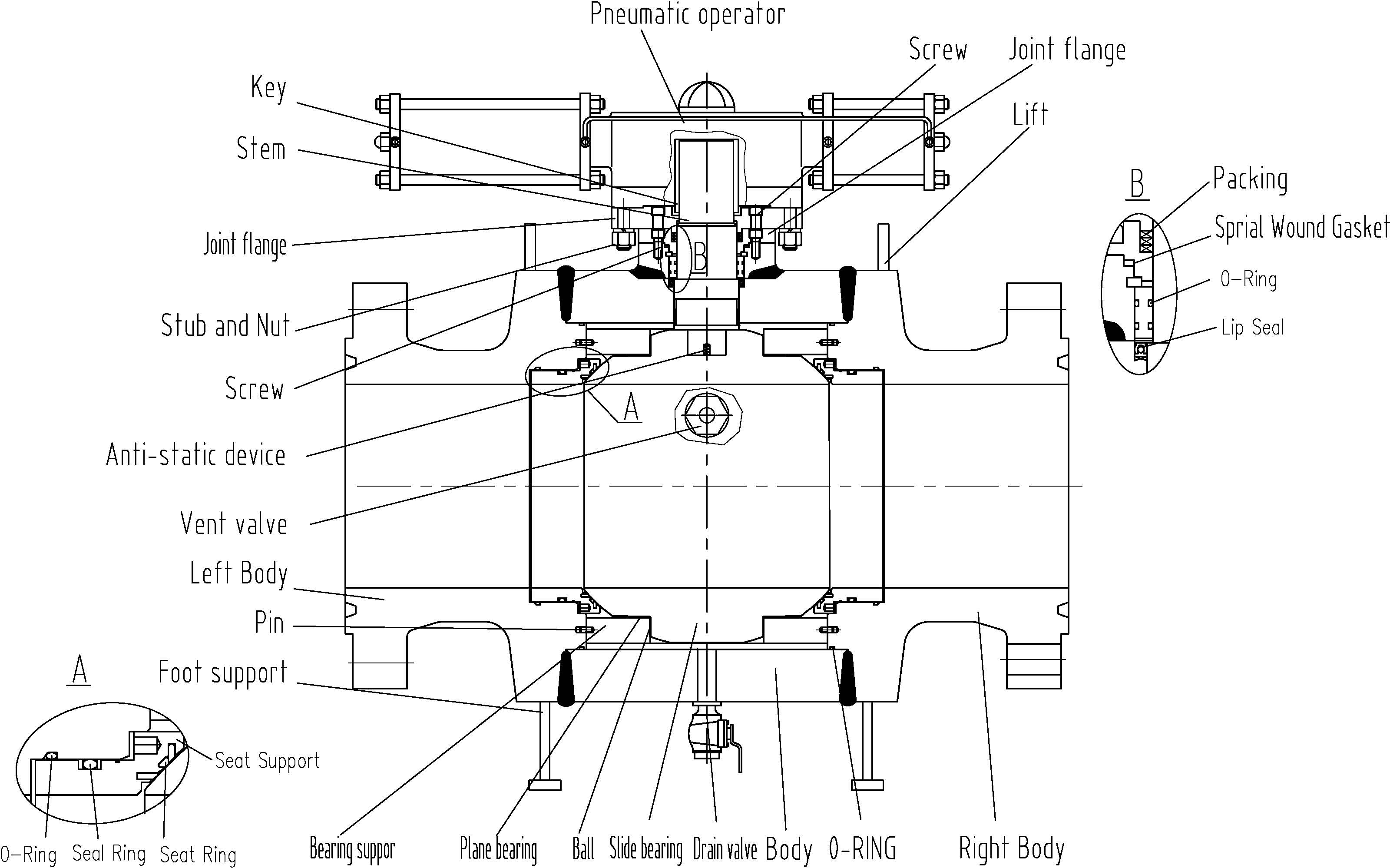

Umfanekiso4 Amavalvu ebhola ashiselwe ngokugcwele ane-pneumatic actuated

Umfanekiso 5 Kugqitshwe amavalvu ebhola ashiselwe ngokugcwele ngegesi kawoyela ecushiwe

Umfanekiso 6 Amavalvu ebhola ashiselwe ngokugcwele anegesi kawoyela ecushiwe

3. Ukufakwa

3.1 Ukulungiselela ukufakwa ngaphambilini

(1) Womabili amapayipi okugcina ama-valve aselungile.Ngaphambili nangemuva kwepayipi kufanele kube yi-coaxial, indawo yokuvalwa kwe-flange emibili kufanele ihambisane.

(2) Amapayipi ahlanzekile, ukungcola okunamafutha, i-slag yokushisela, nakho konke okunye ukungcola kufanele kususwe.

(3) Hlola ukumakwa kwe-valve yebhola ukuze ubone ama-valve ebhola asesimweni esihle.I-valve izovulwa ngokugcwele futhi ivalwe ngokugcwele ukuze kuqinisekiswe ukuthi isebenza kahle.

(4) Khipha izesekeli ezivikelayo ekuxhumekeni kwazo zombili iziphetho zevalvu.

(5) Hlola ukuvuleka kwevalvu bese uyihlanza kahle.Izinto zangaphandle phakathi kwesihlalo sevalvu/indandatho yesihlalo kanye nebhola, ngisho noma imbudumbudu nje ingalimaza ubuso bokuvala isihlalo sevalvu.

(6)Ngaphambi kokufakwa, hlola ngokucophelela i-nameplate ukuze uqiniseke ukuthi uhlobo lwe-valve, usayizi, impahla yesihlalo kanye nebanga lokushisa lokucindezela kuyafaneleka esimweni sepayipi.

(7) Ngaphambi kokufaka, hlola wonke amabhawodi namantongomane ekuxhumekeni kwevalvu ukuze uqinisekise ukuthi iqinisiwe.

(8)Ukunyakaza ngokucophelela kwezokuthutha, ukujikijela noma ukuwisa akuvunyelwe.

3.2 Ukufakwa

(1) Ivalvu efakwe epayipini.Ukuze uthole izidingo zokugeleza kwemidiya kwevalvu, qinisekisa umfula okhuphukayo nowehla nomfula ngokuhambisana nesiqondiso sevalvu ezofakwa.

(2) Phakathi kwe-valve flange kanye ne-flange yepayipi kufanele kufakwe ama-gaskets ngokwezidingo zomklamo wepayipi.

(3) Amabhawodi e-Flange kufanele alingane, alandelane, aqine ngokulinganayo

(4) Amavalvu axhumene nezinqe ashiselwe kufanele okungenani ahlangabezane nalezi zidingo ezilandelayo uma eshiselwe ukuze afakwe ohlelweni lwamapayipi esizeni:

a.Ukushisela kufanele kwenziwe umshiseli onesitifiketi sokufaneleka sokushisela esigunyazwe yi-State Boiler and Pressure Vessel Authority;noma umshiseli othole isitifiketi sokufaneleka sokushisela esichazwe ku-ASME Vol.Ⅸ.

b.Imingcele yenqubo yokushisela kufanele ikhethwe njengoba kuchazwe kubhukwana lokuqinisekisa ikhwalithi yezinto zokushisela

c.Ukwakheka kwamakhemikhali, ukusebenza kwemishini kanye nokumelana nokugqwala kwensimbi yokugcwalisa yomthungo wokushisela kufanele kuhambisane nesisekelo sensimbi.

(5) Uma uphakamisa ngesikhwama noma ngentamo yevalvu kanye neketango lendwayimane eliboshwe esondweni lesandla, ibhokisi legiya noma amanye ama-actuator akuvunyelwe .Futhi, indawo yokuxhuma yamavalvu kufanele inake ukuze ivikeleke ekonakalisweni.

(6) Umzimba we-valve yebhola eshiselwe usuka ekugcineni kwe-butt weld 3 "noma yisiphi isikhathi ngaphandle kwezinga lokushisa lokushisa akufanele lidlule 200 ℃. Ngaphambi kokushisela, izinyathelo kufanele zithathwe ukuvimbela ukungcola okufana nokushisela i-slag Ipayipi elithumele i-corrosion medium ebucayi kufanele lithathwe isilinganiso sokuqina kwe-weld Ukuqina komthungo wokushisela kanye ne-base material abukho ngaphezu kwe-HRC22.

(7)Lapho ufaka ama-valve nama-actuator, i-eksisi yesikelemu kufanele iqonde eksisi yepayipi.

3.3 Ukuhlolwa ngemva kokufakwa

(1) Ukuvula nokuvala izikhathi ezi-3–5 zamavalvu ebhola nama-actuator akufanele kuvinjwe futhi kuqinisekisa ukuthi amavalvu angasebenza ngokujwayelekile.

(2) Ubuso obuxhumekile be-flange phakathi kwepayipi nevalvu yebhola kufanele buhlolwe ukusebenza kokuvala ngokuvumelana nezidingo zomklamo wepayipi.

(3) Ngemuva kokufakwa, ukuhlolwa kokucindezela kwesistimu noma ipayipi, i-valve kufanele ibe sesimweni esivuleke ngokugcwele.

4 .Ukusebenza, ukugcinwa kanye nokugcinwa

4.1 I-valve yebhola ingu-90 °uhlobo lokuvula nokuvala, i-valve yebhola isetshenziselwa ukushintsha kuphela futhi ayisetshenziselwa ukulungisa!Akuvunyelwe ukuthi i-valve isetshenziswe emngceleni wokushisa ongenhla kanye nokucindezela kanye nokucindezela okushintshana njalo, izinga lokushisa kanye nesimo sokusebenza sokusetshenziswa.Ibanga lokucindezela-izinga lokushisa lizohambisana ne-ASME B16.34 Standard.Amabhawodi kufanele aqiniswe futhi uma kwenzeka kuvuza ezingeni lokushisa eliphezulu.Ungavumeli ukuthi kube nomthelela ekulayisheni futhi isenzeko sengcindezi ephezulu ayikuvumeli ukuvela ezingeni lokushisa eliphansi.Abakhiqizi abanandaba uma kwenzeka ingozi ngenxa yokwephulwa kwemithetho.

4.2 Umsebenzisi kufanele agcwalise uwoyela wokugcoba (ugrisi) njalo uma kukhona amavalvu ohlobo lwe-lube.Isikhathi kufanele sibekwe ngumsebenzisi ngokuya ngobuningi be-valve evuleka, ngokuvamile kanye njalo ezinyangeni ezintathu;uma kukhona ama-valve kagrisi okuyingxenye yophawu, igrisi yokuvala noma ukupakishwa okuthambile kufanele kugcwaliswe ngesikhathi uma abasebenzisi bethola ukuvuza, futhi kuqinisekisa ukuthi akukho ukuvuza.Umsebenzisi uhlale egcina imishini isesimweni esihle!Uma kunezinkinga ezithile zekhwalithi ngesikhathi sewaranti (ngokwenkontileka), umenzi kufanele aye endaweni yesigameko ngokushesha futhi axazulule inkinga.Uma isikhathi esingaphezu kwewaranti (ngokwenkontileka), uma umsebenzisi esidinga ukuxazulula inkinga, sizoya endaweni yesehlakalo ngokushesha futhi sixazulule inkinga.

4.3 Ukuzungezisa ngokwewashi kwamavalvu okusebenza kuyovalwa futhi ukuzungezisa ngokuphambene newashi kwamavalvu okusebenza mathupha kuzovuleka.Uma ezinye izindlela, inkinobho yebhokisi lokulawula nemiyalo kufanele ihambisane nokushintshwa kwama-valve.Futhi gwema ukusebenza okungalungile kuzogwema ukwenzeka.Abakhiqizi abanasibopho ngenxa yamaphutha okusebenza.

4.4 Amavalvu kufanele agcinwe njalo ngemva kokusetshenziswa.Ubuso obuvala uphawu nokuhuzuka kufanele kuhlolwe kaningi, njengokuthi ukupakisha kuyaguga noma ukwehluleka;uma umzimba kwenzeka ukugqwala.Uma isimo esingenhla senzeka, sekuyisikhathi sokulungisa noma ukushintshwa.

4.5 Uma into esetshenziswayo ingamanzi noma uwoyela, kuphakanyiswa ukuthi amavalvu kufanele ahlolwe futhi anakekelwe njalo ngemva kwezinyanga ezintathu.Futhi uma i-medium igqwala, kuphakanyiswa ukuthi wonke ama-valve noma ingxenye yama-valve kufanele ihlolwe futhi igcinwe njalo ngenyanga.

4.6 I-valve yebhola ngokuvamile ayinaso isakhiwo sokushisa okushisayo.Lapho i-medium izinga lokushisa eliphezulu noma izinga lokushisa eliphansi, ingaphezulu le-valve alivunyelwe ukuthinta ukuze kuvinjwe ukushisa noma iqhwa.

4.7 Ingaphezulu lamavalvu nesiqu kanye nezinye izingxenye kuvala kalula uthuli, uwoyela kanye negciwane eliphakathi nendawo.Futhi i-valve kufanele ibe nemihuzuko kanye nokugqwala kalula;ngisho kubangwa ukushisa kwe-friction okukhiqiza ingozi yegesi eqhumayo.Ngakho-ke i-valve kufanele ihlale ihlanzekile ukuze kuqinisekiswe ukusebenza kahle.

4.8 Lapho kulungiswa futhi kugcinwa amavalvu elungiswa, kufanele kusetshenziswe okufana nosayizi wokuqala kanye nama-o-rings, ama-gaskets, amabhawodi namantongomane.Ama-O-rings nama-gaskets ama-valve angasetshenziswa njengendawo yokulungisa nokulungisa izingxenye ezisele ngokuthenga.

4.9 Akuvunyelwe ukukhipha ipuleti lokuxhuma ukuze kungene amabhawodi, amantongomane nama-o-ring lapho i-valve isesimweni sokucindezela.Ngemva kwezikulufu, amabhowudi, amantongomane noma ama-o-rings, amavalvu angaphinda asetshenziswe ngemva kokuhlolwa kokuvala.

4.10 Ngokuvamile, izingxenye zangaphakathi zama-valve kufanele zikhethwe ukulungiswa nokushintshwa, kungcono ukusebenzisa izingxenye zabakhiqizi ukuze zifakwe esikhundleni.

4.11 Ama-valve kufanele ahlanganiswe futhi alungiswe ngemva kokuba ama-valve eselungisiwe.Futhi kufanele zihlolwe ngemva kokuba seziqoqiwe.

4.12 Akunconywa ukuthi umsebenzisi aqhubeke nokulungisa i-valve yokucindezela.Uma izingxenye zokulungisa ingcindezi zisetshenziswe isikhathi eside, futhi ingozi engenzeka izokwenzeka, futhi kuthinta ukuphepha komsebenzisi.Abasebenzisi kufanele bashintshe i-valve entsha kusenesikhathi.

4.13 Indawo yokushisela yamavalvu okushisela epayipini ayivunyelwe ukulungiswa.

4.14 Amavalvu epayipini awavunyelwe ukuthi acofe;ingeyokuhamba nje nanoma yiziphi izinto ezisindayo kuyo.

4.15 Iziphetho kufanele zimbozwe ngesihlangu ekamelweni elomile nelingena umoya, ukuqinisekisa ukuhlanzeka kwesikhala sevalvu.

4.16 Amavalvu amakhulu kufanele abekwe phezulu futhi awakwazi ukuthintana nomhlabathi lapho egcinwa ngaphandle Futhi, ukuvikela umswakama okungangeni emanzini kufanele kuqashelwe.

4.17 Uma i-valve yokugcina isikhathi eside iphinde isetshenziswe, ukupakisha kufanele kuhlolwe ukuthi akuvumelekile yini futhi kugcwalise amafutha okugcoba ezingxenyeni ezijikelezayo.

4.18 Izimo zokusebenza zevalvu kufanele zihlale zihlanzekile, ngoba zingelula isikhathi sokusebenza kwayo.

4.19 I-valve yokugcina isikhathi eside kufanele ihlolwe njalo futhi ikhiphe ukungcola.Indawo yokubeka uphawu kufanele inake ukuthi ihlanzekile ukuze ivikeleke ekulimaleni.

4.20 Iphakethe lokuqala liyagcinwa;ingaphezulu lama-valve, i-stem shaft kanye ne-flange indawo yokubeka uphawu ye-flange kufanele inake ukuvikela.

4.21 Umgodi wama-valve awuvunyelwe ukuphuma lapho ukuvuleka nokuvala kungafiki endaweni ebekiwe.

5. Izinkinga ezingaba khona, izimbangela kanye nezinyathelo zokulungisa (bheka ifomu 1)

Ifomu 1 Izinkinga ezingenzeka, izimbangela kanye nezinyathelo zokulungisa

| Incazelo yenkinga | Okungaba imbangela | Izinyathelo zokulungisa |

| Ukuvuza phakathi kwendawo yokuvala | 1. Indawo engcolile yokuvala uphawu2.Indawo yokuvala ilimele | 1. Khipha ukungcola2.Yilungise kabusha noma uyishintshe |

| Ukuvuza ekupakisheni kwesiqu | 1. Amandla okucindezela okupakisha awanele2.Ukupakisha okonakele ngenxa yesevisi yesikhathi eside 3.O-ring for ukugxusha ibhokisi ukwehluleka | 1. Qinisa izikulufu ngokulinganayo ukuze uhlanganise ukupakisha2.Shintsha ukupakisha

|

| Ukuvuza ekuxhumekeni phakathi kwe-valve yomzimba nomzimba wesokunxele nakwesokudla | 1.Amabhawodi okuxhumana abopha ngokungalingani2.Ubuso be-flange obulimele 3. Ama-gaskets awonakele | 1. Kuqiniswe ngokulinganayo2.Yilungise 3. Faka esikhundleni ama-gaskets |

| Vuza i-valve yamafutha | Imfucumfucu ingaphakathi kwamavalvu kagrisi | Hlanza ngoketshezi oluncane lokuhlanza |

| Konakele ivalve yamafutha | Faka futhi ubeke esikhundleni sokugcotshwa okusizayo ngemva kokuba ipayipi lehlise ingcindezi | |

| Vuza i-valve yokudonsa | Konakele ukuvalwa kwe-valve yokudonsa | Ukuvaleka kwama-valve okudonsa amanzi kufanele kuhlolwe futhi kuhlanzwe noma kushintshwe ngokuqondile.Uma ilimele kakhulu, ama-valve okukhipha amanzi kufanele ashintshwe ngokuqondile. |

| Ibhokisi legiya/i-actuator | Ukuhluleka kwebhokisi legiya/i-actuator | Lungisa, lungisa noma shintsha ibhokisi legiya kanye ne-actuator ngokuya ngebhokisi legiya kanye nezici ze-actuator |

| Ukushayela akuguquki noma ibhola alivuli noma livaleke. | 1. Ibhokisi lokugxusha kanye nedivaysi yokuxhuma i-skewed2.Isiqu nezingxenye zaso zonakele noma zingcolile. 3. Izikhathi eziningi ukuvula nokuvala nokungcola ebusweni bebhola | 1. Lungisa ukupakisha, ibhokisi lokupakisha noma idivayisi yokuxhuma.2.Vula, lungisa futhi ukhiphe indle 4.Vula, hlanza futhi ukhiphe indle |

Qaphela: Umsebenzisi kufanele abe nolwazi olufanele kanye nesipiliyoni ngamavalvu

Isikhathi sokuthumela: May-19-2022